Product information

Model 300

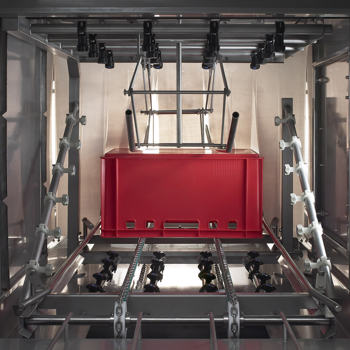

JEROS Model 300 tunnel washer built for high-capacity industrial cleaning

The JEROS Model 300 tunnel washer is built for operations that demand maximum output and uncompromising cleanliness. Whether you're cleaning crates, containers, trays, or tough-to-wash production equipment, Model 300 delivers consistent, high-pressure performance with minimal manual input.

This robust system is designed for the real-world industrial food production environment, where speed, hygiene, and durability are paramount. With a throughput of up to 350 crates per hour and 44 high-impact nozzles (including 16 rotating bottom nozzles), the Model 300 tunnel washer tackles heavy workloads with ease.

What makes a difference:

Designed for large-scale production – ideal for central kitchens, processing plants, and high-volume facilities.

Two-person operation – a simple, efficient workflow reduces labor hours and handling.

Handles up to 350 crates per hour – maximum throughput for busy operations.

Extremely high wash pressure (4-4.5 bar) – ensures deep, consistent cleaning, even on heavily soiled items.

16 rotating bottom nozzles – powerful cleaning from every angle.

Wide tunnel design – accommodates large or awkwardly shaped items with ease.

Freshwater final rinse at 85°C – certified sanitation, cycle after cycle.

Modular add-ons – compatible with the TD Drying Section, stainless conveyor belt, and other performance upgrades.

Built-in energy and water efficiency – recycled rinse water system minimizes consumption.

Easy service access – side door cleaning zones and maintenance panels for quick upkeep.

Touchscreen control panel – intuitive interface, customizable for any workflow.

Do you need a tunnel washer that can keep up with your production volume?

Let's talk – we'll help you configure the proper setup for your operation ⇨