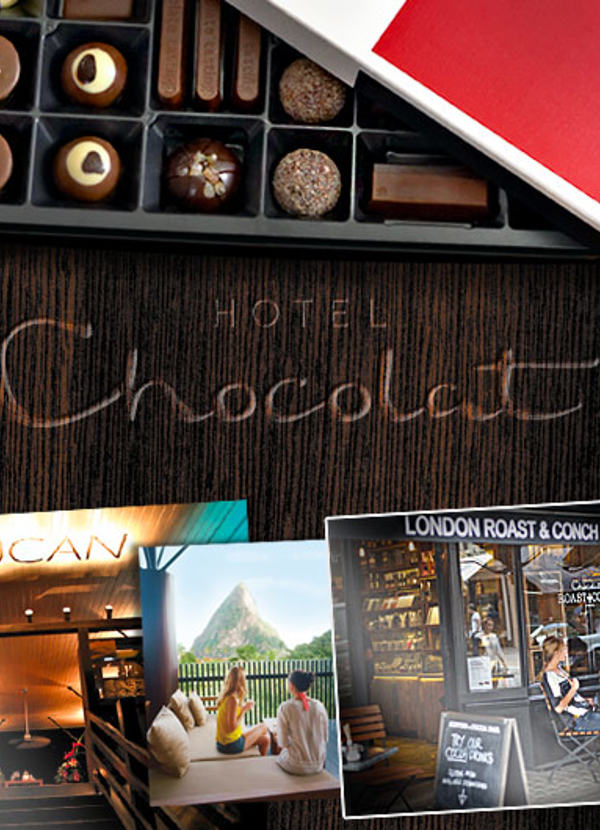

Making chocolate exciting again!

Hotel Chocolat is not just any chocolate manufacturer. The British chocolate manufacturer is the epitome of luxury chocolates - and it is the only company in the United Kingdom to grow cocoa on its own farm.

Since the beginning, Hotel Chocolat has been on a mission to make chocolate exciting again. And the company succeeded! When they opened their first shop in North London in 2004, it started a revolution in British chocolate.

Today, Hotel Chocolat comprises 126 stores and several cafés, restaurants, outlets, and factory stores. They are on a continual journey of development and growth, yet their fundamental thoughts about chocolate will guide everything they do.