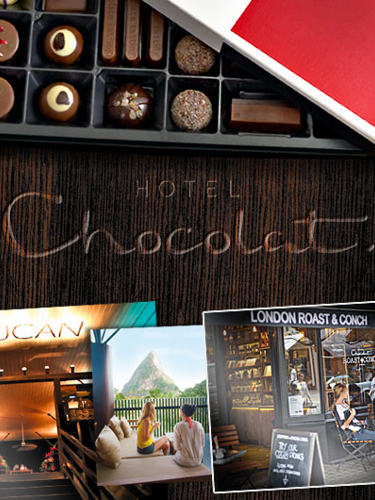

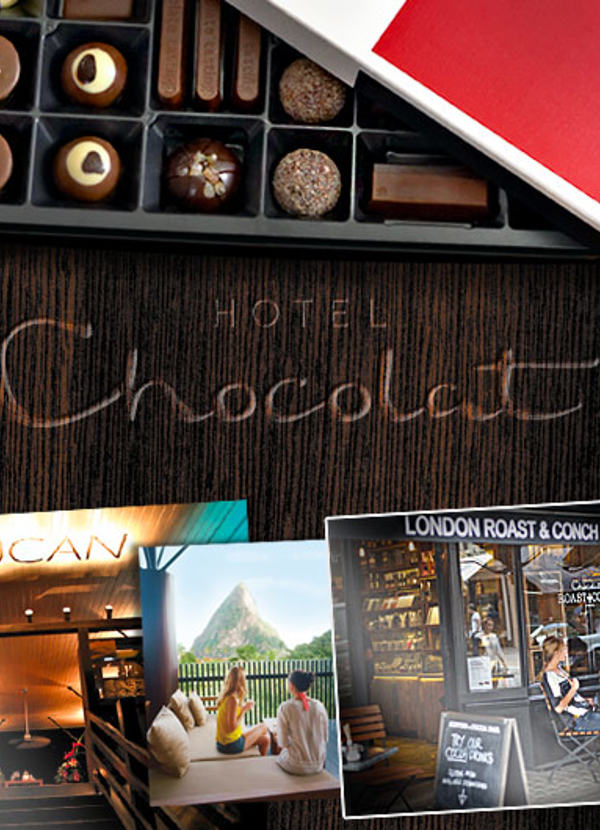

Making chocolate exciting again!

Hotel Chocolat is not just another chocolate producer; it stands as a symbol of premium British craftsmanship in the world of luxury chocolates. Uniquely, it is the only UK-based chocolatier to cultivate its own cocoa on an in-house farm.

Since its inception, Hotel Chocolat has been committed to reinvigorating the chocolate industry, and it has certainly achieved that goal. The opening of its first store in North London in 2004 marked the beginning of a revolution in British chocolate.

Today, Hotel Chocolat operates 126 stores across the UK, alongside a network of cafés, restaurants, outlets, and factory shops. As the company continues to evolve and expand, its core philosophy towards chocolate remains at the heart of everything it does.