Reduced downtime turns into increased revenue

Globally, we are consuming more and more snacks.

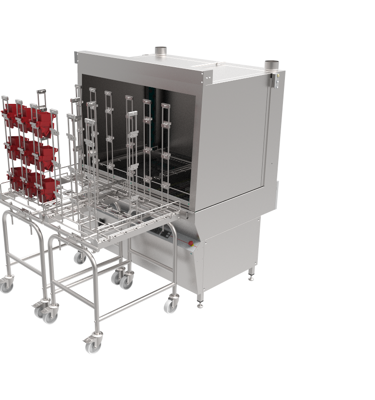

This growing demand means that the challenge we most often face is how our professional hooded dishwashers help increase production efficiency by reducing downtime while ensuring consistent, bacteria-free washing results every time.

And it's no secret that JEROS's range of dishwashers helps generate increased revenue for the snack industry while ensuring optimal hygiene on the filling line in production.

Let's outline an example of how reduced downtime translates into increased revenue:

When a snack manufacturer has finished producing one product with one seasoning, the entire process line, including feeders, multi-head weighers, weighing bowls, and chutes for automatic weighing and bagging, must be cleaned before the manufacturer starts a new production with a new spice or flavor.

This typically involves the production of crisps, nut mixes, dried fruit, sweets, and chocolate.

Before we developed the specially designed hygiene solutions for snack producers, all removable items on the production line were removed, placed in boxes, and manually carried down from the ledge where the weighing takes place to the production cleaning area where the items are cleaned.

This manual cleaning process typically lasts 2 to 3 hours per production. It is an actual downtime where the manufacturer cannot produce other snacks. At the same time, there is a high risk of parts breaking during manual washing, which can lead to an actual production shutdown!

The snack manufacturer, therefore, loses revenue.

The article continues below ⇩