Committed to enhancing hygiene standards

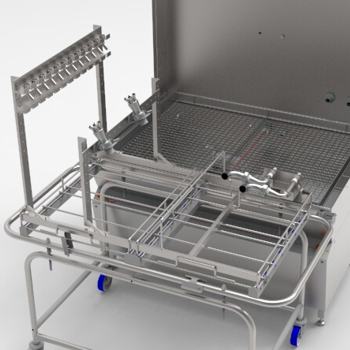

Located near the German border, one of Arla Foods' largest white cheese production facilities plays a pivotal role in their operations. Committed to continuously improving hygiene standards, Arla turned to JEROS for a tailored washing solution for the Alpma line, which handles the cutting and packaging processes at the Kruså plant.

Arla Foods, a leading international dairy company from Denmark, relies on this facility to produce high-quality white cheese, supporting their global reputation for excellence in dairy products, including milk, cheese, butter, yogurt, and cream.

Known for its premium, nutritious products, Arla Foods offers popular brands such as Arla, Lurpak, and Castello. The company also caters to a diverse range of consumer needs, with options including organic, lactose-free, and high-protein dairy products, demonstrating their commitment to meeting your unique requirements.