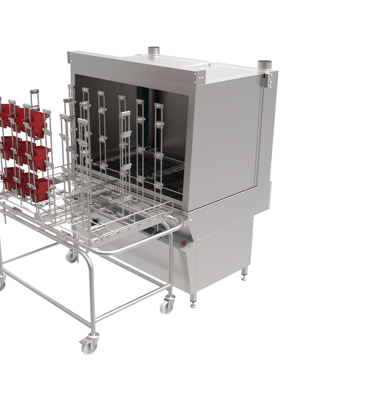

Get a custom-made utensil washer for cleaning your process line

Cleaning equipment for the food processing industry has always been at the heart of JEROS’s business.

When we develop, manufacture, and supply utensil washers, crate washers, and barrel washers, our primary goal is to minimise downtime and maintain a high standard of hygiene in every production environment. We achieve this by automating washing processes to deliver the best possible results.

We are constantly optimising our machines to ensure our customers receive the solutions they need or to enhance production performance.

We view all customer relationships as partnerships. Whether you are a new acquaintance or a long-term partner, we work closely with you to understand how your production is evolving, enabling us to offer bespoke solutions tailored to your needs.

With JEROS as your partner, we can identify your hygiene requirements directly or through our global network of dealers.

By collaborating with us, you will receive a solution specifically designed to clean your production line as efficiently as possible, with short wash times and minimal water and chemical usage.

All of this is done to ensure and document your hygiene standards, while also improving the ergonomics of your working environment.