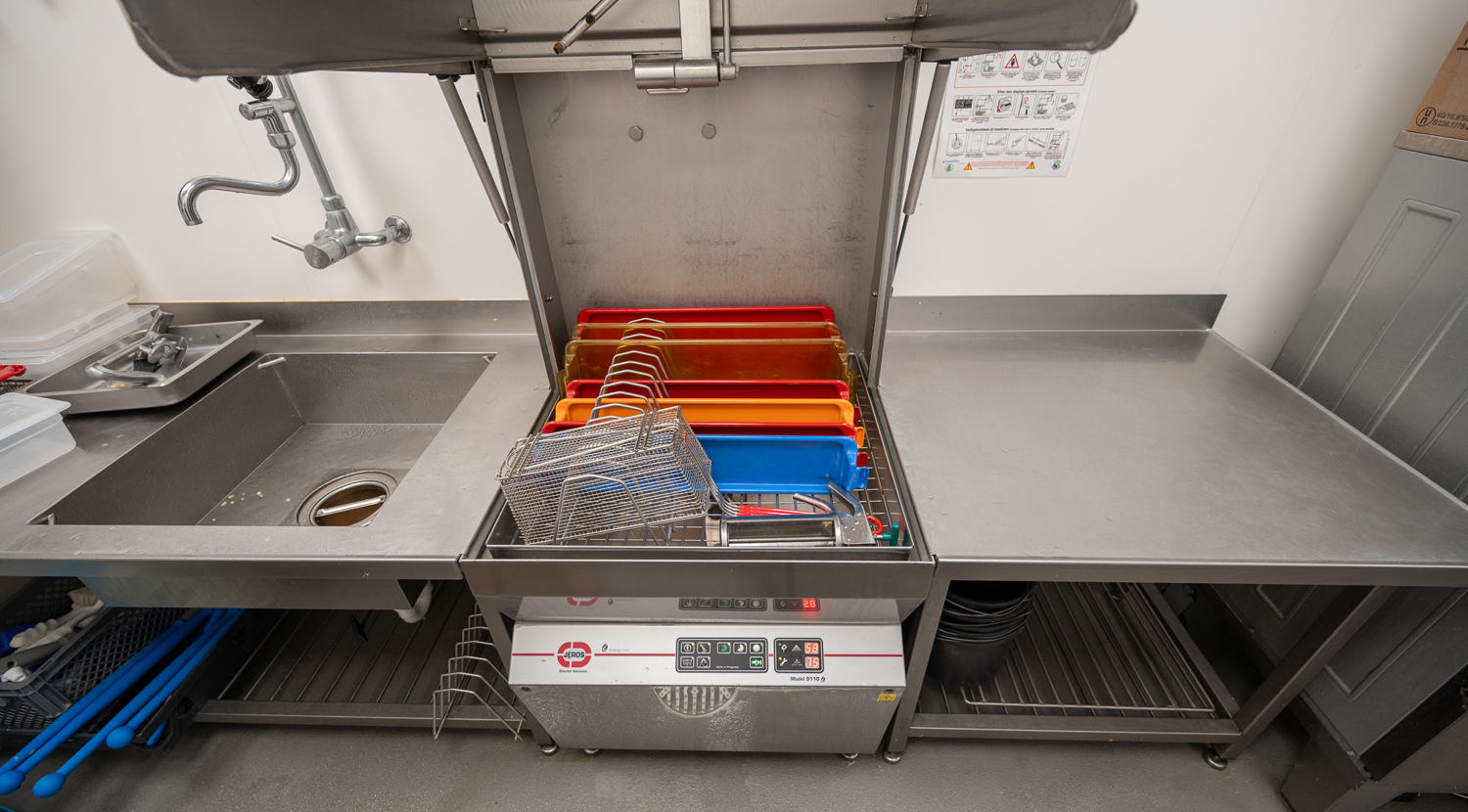

JEROS's hood-type dishwasher ensures a consistent and high level of hygiene

When adopting a global perspective, it is apparent that many in the fast food industy still rely on manual dishwashing. This approach presents challenges, particularly in maintaining consistent hygiene standards and minimising water and chemical usage, which are essential for sustainable operations.

In fast food establishments where dishes are washed by hand, the process typically involves three stages and requires multiple employees:

The first stage involves a rinse to remove food residue, while the second and third stages include sanitising liquids, where items are immersed before being dried.

When we demonstrate the time, resources, and cost savings that come with investing in a JEROS hood-type dishwasher, we are genuinely excited to see how our clients share in that enthusiasm.

Article continues below ⇩