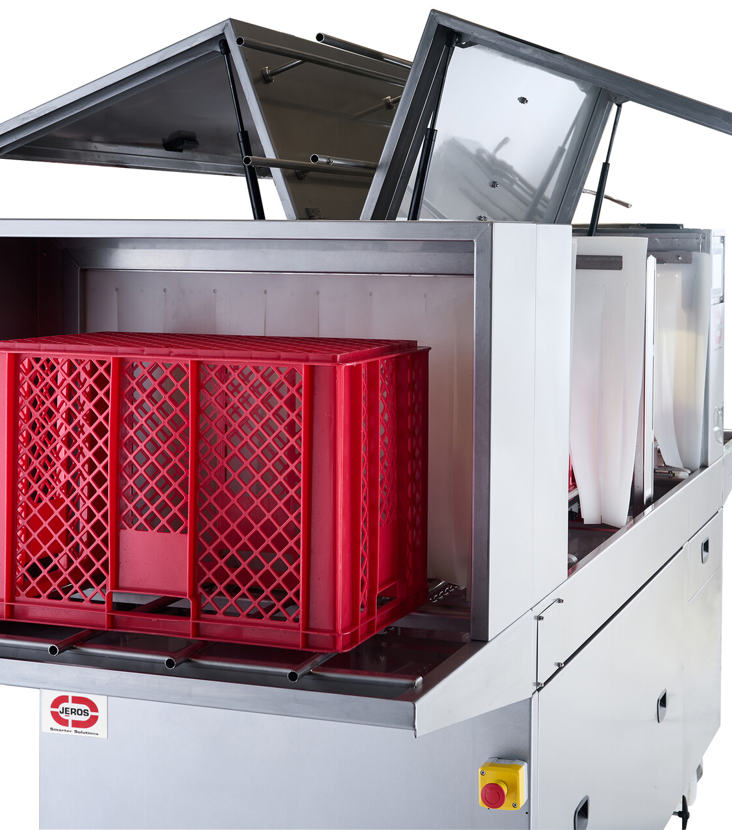

JEROS Crate Washer. Industrial hygiene built for modern food production

Efficient, automated cleaning – no matter your workflow

Whether you're washing plastic crates, bakery trays, utensils, pans, or baskets, JEROS crate washers are built to match the rigorous standards of food industry environments.

Engineered for both high throughput and consistent hygiene, they help reduce manual handling, optimise routines, and deliver reliable cleaning results – every single time.

We currently offer two advanced models tailored to differing capacity and space requirements:

The Model 220XT | Compact and adaptable, the 220XT is ideal for businesses requiring dependable daily cleaning of a wide variety of items. With ergonomic one-man operation and an intuitive control panel, it suits smaller production lines or frequent cleaning tasks – all while maintaining a high standard of hygiene.

The Model 300 | Built for heavy-duty industrial use, the 300 features reinforced parts and a wide tunnel with 44 high-performance nozzles (16 of which are moving). Designed for robust cleaning at high pressure (4–4.5 bar), it delivers strength and speed where it matters most.

Both models support one-man operation and integrate seamlessly into existing workflows with minimal disruption.

Upgrade your hygiene routine – and cut manual labour

Automated crate washers are the smart way to reduce repetitive cleaning and improve operational efficiency.

With intelligent conveyor systems, temperature-optimised rinse cycles, and simple touchscreen controls, your team spends less time cleaning and more time producing:

- One-person operation means lower staffing requirements.

- No crate height sorting needed – no downholders required.

- Quick-access panels facilitate rapid maintenance and cleaning.

- A final rinse at 85°C ensures that every item is sanitised.

Improve uptime. Reduce waste.

Actual efficiency isn’t just about speed – it’s about resource savings too.

JEROS crate washers are built with insulated tanks, efficient rinse systems, and low-maintenance designs that help reduce operational costs and environmental impact:

- Insulated lids and tanks minimise energy consumption.

- Rinse water is recovered and reused in the wash tank.

- Easy-Fit nozzles and self-cleaning filters simplify servicing.

The difference is in the details

| Feature | Model 220XT | Model 300 |

|---|---|---|

| Capacity | Up to 300 crates/hour | Up to 350 crates/hour |

| Pressure | Moderate & efficient | Extremely high (4–4.5 bar) |

| Best for | Medium-volume, varied items | High-volume, heavy-duty cleaning |

| Design | Compact & ergonomic | Reinforced & industrial |

| Cleaning Access | Tunnel lid lift | Side door zones |

| Use case | Multi-item flexibility | Robust crate and container washing |

High-performance features. Real-world impact

JEROS crate washers are engineered to handle the demanding cleaning needs of high-throughput food production. Designed for efficient washing of large plastic crates, baskets, bakery trays, pans, and utensils, our systems process 250–300 crates per hour with ease.

For even greater efficiency, both the 220XT and 300 models can be paired with a tunnel dryer, enabling fast, integrated drying that keeps your workflow moving.

Whether you're expanding production or streamlining hygiene routines, every JEROS crate washer comes equipped with intelligent, performance-driven features – plus a wide range of optional extras to customise your system and optimise daily operations:

TD drying section

Seamlessly connects to the washer for high-efficiency air drying after each cycle.

Conveyor system

Secures and stabilises item flow throughout the cleaning process.

Stainless steel cage with lid

A durable, hygienic solution for safe storage and handling.

Stainless steel conveyor belt

Perfect for washing smaller items securely and effectively.

Slide-out filter tray

Quick and effortless access for cleaning and maintenance.

Easy-fit nozzle system

Tool-free removal of nozzles for fast cleaning and servicing.

Twist closure drain

Makes emptying the rinse tank clean, fast, and tool-free.

Easy motor access

The motor can be accessed without hassle, simplifying maintenance.

Let’s find the right solution for your production

Your tunnel washer is only as good as the support behind it.

At JEROS, reliability extends beyond the machine. With over 60 years of experience in industrial hygiene and a trusted network of service partners across the UK and Europe, we're here to support your business, long after installation.

We work exclusively with high-quality components and suppliers to ensure long-lasting, trouble-free performance.

Whether you're installing your first crate washer or upgrading an existing line, our team is ready to help you make the right decision, configure the right system, and keep it running smoothly for years to come.

Amjad Alikhan, Managing Director, JEROS UK

With JEROS as a partner, we identify your needs for hygiene solutions directly or through our global dealer network.

Discover how JEROS's hygiene solutions work for you